Improving tray efficiency in the spray regime

Published by Callum O'Reilly,

Senior Editor

Hydrocarbon Engineering,

Although very specialised, mass transfer equipment is essential for every plant, be it an oil refinery, petrochemical, chemical or gas plant. At the heart of these plants are the distillation and absorption columns used for the separation of liquid mixtures into their various components.

The design of a distillation column is split into process and hydraulic design. The process design involves determining the number of theoretical stages (NTS) required for a given separation. With desktop computing power available nowadays, there are many commercial process simulation packages that can be used for this. The simulation will generate the internal column traffic (hydraulic loads), along with the condenser and reboiler heat duties.

Subsequently, whilst a lot of thought is given to the hydraulic design of trays, the tray efficiency tends to be overlooked. However, for a complete column design, the NTS calculated need to be translated into actual stages (trays).

Tray efficiency calculation methods can be divided into:

- Comparison with similar operating columns.

- Empirical correlations (methods).

- Theoretical or semi-theoretical methods.

- Scaling up from laboratory columns.

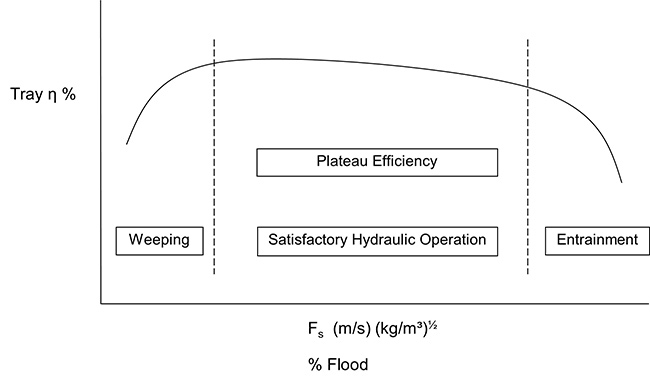

Figure 1. Schematic representation of a typical tray efficiency curve.

Figure 1 shows a schematic representation of a typical tray efficiency profile. At low loads, the efficiency falls off sharply due to weeping, whilst at high loads the reduction is due to entrainment. In the satisfactory hydraulic operating region, the ‘plateau’ efficiency is a sum of the intrinsic system efficiency plus the contribution due to tray design factors. The intrinsic system efficiency cannot be influenced once the operating pressure has been set, as this dictates the key physical properties of the system, namely relative volatility and liquid viscosity. However, the contribution due to tray design factors can be increased.

Irrespective of the method used to predict tray efficiency, understanding the factors that influence it allows the use of appropriate features that not only maximise the plateau efficiency, but also extend the satisfactory operating range in either direction...

Written by Aadam F. Aryan, Distillation Equipment Company Ltd.

This article was originally published in the January 2022 issue of Hydrocarbon Engineering magazine. To read the full article, sign in here or register for a free trial subscription.

Read the article online at: https://www.hydrocarbonengineering.com/special-reports/18012022/improving-tray-efficiency-in-the-spray-regime/

You might also like

The Hydrocarbon Engineering Podcast - Education and training for every phase of the insulating system design process

In this episode of the Hydrocarbon Engineering Podcast, Brandon Stambaugh, Owens Corning Director for Technical Services, joins us to discuss engineers’ demand for education and training to support the critical phases that affect the performance and longevity of insulating systems.

Tune in to the Hydrocarbon Engineering Podcast on your favourite podcast app today.