Key principles for advancing sustainability

Published by Callum O'Reilly,

Senior Editor

Hydrocarbon Engineering,

Today, manufacturing industries are facing a perfect storm of disruptive challenges. First and foremost, efforts to mitigate climate change are driving the decarbonisation of our industrial and energy systems, with impacts and effects that we are only just beginning to appreciate. Secondly, business models and value chains are undergoing transformation as individual companies adjust to regulatory, market and social pressures to reduce environmental impact and circularise their supply chains. And finally, digital transformation now defines customer, regulator, investor and employee expectations, which is driving change at an ever-accelerating speed.

The key challenge for each individual, company and sector in manufacturing is preparing for future changes while meeting short-term responsibilities to direct stakeholders, in addition to the expectations of society at large.

Sustainability in its myriad forms sits at the heart of this discussion. Too often, this objective is seen as an existential threat: a cost to be minimised, and a liability to be mitigated. However, a growing number of companies are realising that it represents an opportunity to be embraced, and a challenge during which not all will thrive.

There are two essential factors that characterise the companies experiencing success with driving fruitful sustainability initiatives. The first is the switch from periodic retrospective management to continuous real-time responsiveness; the second is the realisation that sustainable practices develop over time. Sustainability transformation is more akin to a tadpole becoming a frog than to a caterpillar turning into a butterfly. It is a gradual and incremental process that comes from within, rather than a single, externally-driven, big bang project.

Managing for success

One often overlooked hurdle to embarking on a sustainability journey is simply the act of getting started. It is crucial to take the leap, learning how to adapt and grow, and beginning the process of positioning an organisation for the future. The organisations that are successfully progressing towards sustainability goals are not sitting around waiting for a perfectly clear playing field, or for the finalisation of standards and business models. Instead, they recognise that there is a massive first-mover advantage available to the pioneers of new business models and value chain configurations.

Flexibility, adaptability and responsiveness are key to embarking on a sustainability initiative. The most effective approaches require a continuous cycle of experimentation, learning, prototyping, and rapid and consistent deployment.

Given the pace and scale of necessary changes, it is essential to engage with and empower individuals throughout the entire organisation. Sustainability initiatives cannot be left to a select few in their own echo chamber.

The remainder of this article will lay out seven principles that organisations are learning as they embrace the transformation process, aiding the shift towards continuous, real-time responsiveness.

Principle 1: run-time enterprise-wide visibility is essential

The magic happens when a company shifts from retrospective performance reporting to run-time visibility at the plant level. This shift enables efficiency improvements that save costs and drive sustainability performance, and profitability and sustainability align. This shift sounds simple in principle, but it is dramatic in practice.

Once run-time visibility is established throughout the enterprise, a company can begin to identify best practices and benchmarks. These, in turn, drive further learning and continuous improvement, yielding the short-term payback that provides confidence and the investment needed to secure longer term goals.

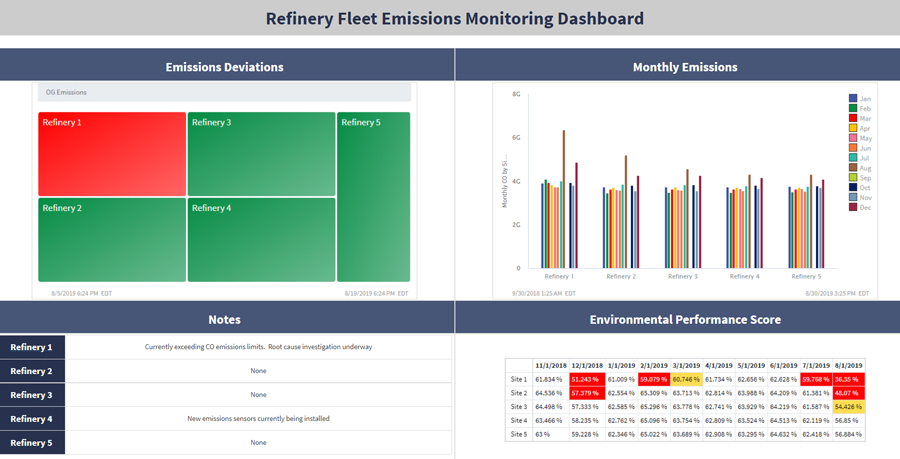

For example, Chevron used Seeq, an advanced analytics solution, to automate their regulatory compliance reporting (Figure 1). As new data became available in the data historian, the company’s calculations and reports were automatically updated with the latest information.

By leveraging this solution, Chevron reduced the time that it takes to generate a report – from days to a few hours. More importantly, it provided access to the company’s latest emissions performance data, facilitating a shift from reactive to proactive management and oversight. This empowered subject matter experts (SMEs) to identify issues as they arose, rather than reporting only after the fact.

Figure 1. Chevron used Seeq to monitor and automatically report emissions across an entire fleet of refineries (source: Seeq).

Principle 2: prepare for a journey of learning and many steps

Big bang, linear, waterfall discrete transformation projects rarely work in the best of conditions. And in the ambiguous and rapidly shifting landscape of sustainability standards, legislation and markets, these projects are nearly impossible to accurately define and scope, requiring a different approach. During transformation efforts, project teams must focus on people, culture and behaviour, leaning on continuous experimentation and observation, and learning to refine the project path.

Roadmaps are often used as an analogy, but this is not the most fitting. A roadmap presumes a stable road network, and clarity for the best route. However, sustainability spaces require a more agile approach because the paths are more readily likened to navigating ice flows. We know where we are starting, along with the direction we need to move, but the best route cannot be predetermined in advance. In fact, we may not even see the end point. All that we can do is observe the way in which things move around us, determine the best next step, take it, then pause to re-evaluate and understand the new landscape before deciding on another step.

From a workforce capability perspective, this is a process of deliberately and consciously introducing new approaches, ideas and capabilities into the organisation, and allowing them to develop. Then, those yielding favourable results can be nurtured and propagated, while those that do not can be pruned. Once what works has been established, and it has been understood why this is the case, solutions can be deployed rapidly, and organisations can continue to learn and monitor.

Principle 3: collaboration through a single platform for investigation and operationalisation

It is crucial to operationalise monitoring so that anomalies can be identified and proactively addressed, and this must be the priority activity once baseline reporting is established. However, successful organisations have learned that this is a necessary but insufficient capability for effectively deploying mitigations and establishing a continuous improvement process. Instead, the ability to collaborate, drill down, and perform ad-hoc investigations within a single operating environment or platform is the required component. Collaboratively, meaningful mitigative actions can be agreed upon, facilitating learning, and dissemination of this knowledge makes institutionalisation possible.

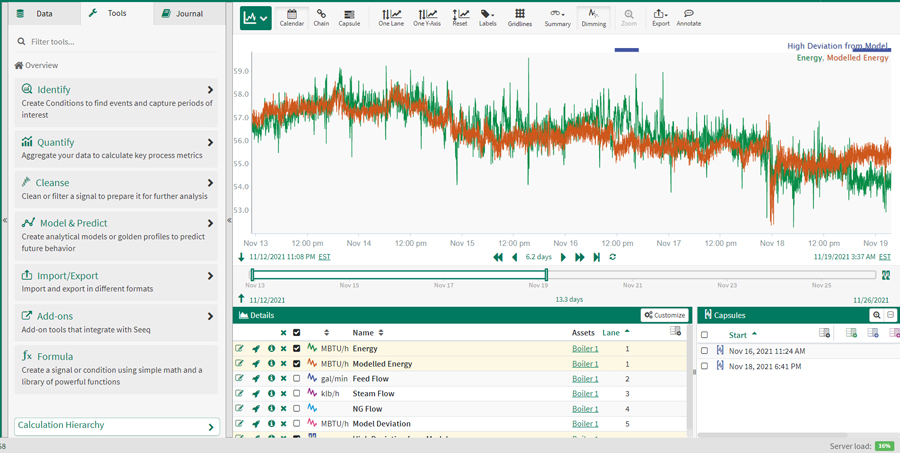

For example, creating predictive energy consumption models is difficult. In most cases where these exist, the models are rarely updated, rendering them quickly obsolete. Relevant data must be cleansed, aligned and featured in a sample that can be inserted into a model.

A speciality chemical company, Allnex, used Seeq to develop and update its models, many entailing multivariate complexity to consistently identify energy reduction opportunities (Figure 2).

The model empowered the organisation to discover relationships defined by energy models, creating an effective energy reduction programme that consistently delivered results and attractive ROI.

Figure 2. Allnex used Seeq to compare modelled and actual energy consumption. When high deviations are identified, SMEs perform root cause analysis (source: Seeq).

Principle 4: prepare to adapt in an evolving landscape

Today, there are few established standards for decarbonisation, and there will never be a single set of universally-accepted calculation and reporting procedures. For this reason, organisations cannot wait until such a mythological standard exists. There is, however, a starting point.

Many industry-based standards are arising with increasing reach, such as CDP, CTI, GRI, and more. These standards are finding their way into more general global frameworks, including TCFD, SASB, and OGCI. These, in turn, are informing regulation and legislation, such as the EU’s CSRD, the SECC Standardisation of Climate-Related Disclosures, and UK Sustainability Disclosure Requirements for Large Firms. The direction of travel is clear by the documentation available, with the requirement for near-real-time reporting at an individual facility level inevitable in most jurisdictions.

The key requirement is the capability to plug-and-play with various frameworks and standards as they emerge, and to even apply different standards to the same data set when required. Getting started, identifying the data sources, filling the gaps, and beginning to measure and calculate are the first steps.

In the early 2020s, global chemical manufacturer Syngenta pledged to reduce its carbon intensity by half, by 2030, aligning a long road ahead. The company’s first step toward this goal was understanding the current state of its operations. Historically, this cumbersome and manual analysis was only conducted once per year, making it difficult to track ongoing success.

However, Syngenta deployed Seeq to gain real-time awareness of its utility stream carbon intensity. This visibility into near-real time conditions enabled the manufacturer to make data-driven decisions targeting carbon reduction on an ongoing basis. As a result, it is steadily making measurable progress towards its ambitious goal.

Principle 5: templatise for mass deployment and manage consistently

It is not difficult to build and manage single isolated monitoring, reporting, and anomaly detection solutions. But when there are tens, hundreds, and even thousands of similar assets or pieces of equipment that require the same approach, the deployment and management challenge becomes incredibly complex. Templatised solutions – either rigorously quality-controlled, or managed following open-source principles, depending on organisational culture – are the first components.

Monitoring by exception is key to managing fleet- and enterprise-wide installations, as is the ability to triage the outputs and place focus where it is most needed. Finally, and perhaps most importantly, developing a common way to collaborate, investigate, learn, and disseminate information is essential over the long-term. If an approach is missing any of these capabilities, it may never fully deploy simply due to the effort required, or it will slowly degrade until it is switched off because of the difficulty with maintaining currency and relevance.

Principle 6: query in place, in a non-invasive manner

There are two massive barriers to effective and extensive use of advanced analytics techniques. The first is the need to extract the required data, transform it, and load it into the analytics system of choice, and the second is the requirement to format and structure it in a secondary database or data-lake. These challenges become even more intense with time series data, where a single process value or other datapoint is, in fact, a table of thousands of time stamps with corresponding values.

It is far quicker, easier and more democratic to leave the data where it is, query it from there as needed, analyse it using tools specifically designed to manage and handle time-series data sets (i.e., NOT Excel), and then report the results where required. This ensures that the integrity of pre-existing systems of record and data governance processes are upheld.

Principle 7: make every engineer a sustainability engineer

To accelerate progress, analytics capabilities should be placed in everyone’s hands – not restricting them to those of isolated specialists. By democratising analytics, the overall demand – including for the advanced techniques, sophisticated AI, and deep learning approaches – can be extended beyond specialist data science teams. This encourages everyone in the organisation to maximise their contributions to help meet teamwide goals.

By applying this final principle to sustainability and taking full advantage of principles one through six, every engineer in the organisation can become a sustainability engineer. When everyone is empowered to play their part preparing the business for the future, learning, sharing, and growing together in the pursuit, teams can dramatically improve current operations.

Joining the sustainability transformation

The world is changing around us, of that there is no doubt. The industries we work in will look radically different in the future as our economies decarbonise. Regulation, legislation and social pressure will drive ever-increasing expectations around environmental protection, circularisation, and recycling. Meanwhile, digital technologies will continue to accelerate the pace of change and underpin demands for greater transparency, timeliness, and verification of environmental impact. The challenge of responding to this combination of forces will prove difficult if not fatal, but for those with the foresight, imagination, and courage to push the status quo, it represents an opportunity to adapt and thrive.

There are many factors that determine the success of every business, but in the not-too-distant future, an intense focus on enabling, empowering, and augmenting the workforce will be amongst them in many industries. The ability to learn rapidly and disseminate knowledge extensively and consistently will also be among these metrics.

In manufacturing operations, effortless manipulation of time series data and democratisation of analytics capabilities are vital components to enable these qualities. And addressing sustainability performance in near-real-time transforms decarbonisation from an expensive cost burden to a driver of short-term efficiency savings and long-term strategic readiness.

Written by Chris Hamlin, Seeq Corp.

Read the article online at: https://www.hydrocarbonengineering.com/special-reports/21082023/key-principles-for-advancing-sustainability/

You might also like

The Hydrocarbon Engineering Podcast - Process safety improvements in the downstream sector

In this episode of the Hydrocarbon Engineering Podcast, Lara Swett, Vice President of Technical & Safety Programs, American Fuel & Petrochemical Manufacturers (AFPM), joins us to explain how the downstream sector has continued to improve its process safety record.

Tune in to the Hydrocarbon Engineering Podcast on your favourite podcast app today.