Severe-service solutions

Published by Callum O'Reilly,

Senior Editor

Hydrocarbon Engineering,

According to the US Department of Energy (DOE), natural gas reforming or steam methane reforming (SMR) currently accounts for 95% of the hydrogen produced in the US; it is arguably one of, if not the most, cost-effective and energy efficient methods to manufacture hydrogen.

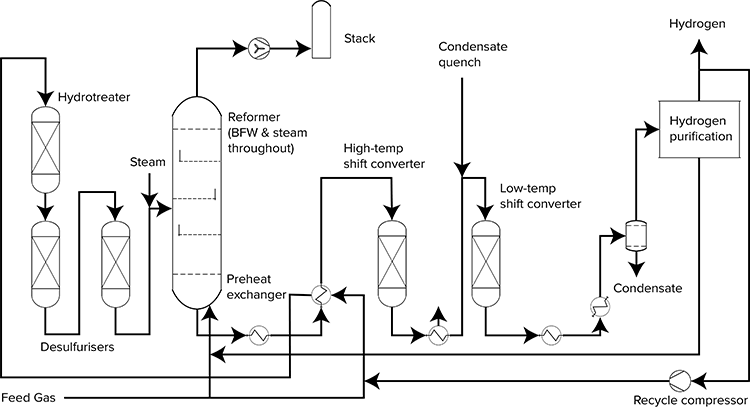

Figure 1. Overview of a typical SMR process.

Figure 1 depicts an overview of a typical SMR process. SMR is considered a mature production process whereby a methane source (i.e. natural gas, biogas, syngas, etc.) reacts endothermically with high-temperature steam in the presence of a catalyst to yield hydrogen, carbon monoxide, and carbon dioxide:

CH4 + H2O (+ heat) → CO + 3H2

Subsequently, the carbon monoxide and steam are reacted in the presence of a catalyst to produce additional hydrogen and carbon dioxide in regard to the ‘water-gas shift’ reaction:

CO + H2O → CO2 + H2 (+ heat)

Finally, the hydrogen gas is purified via pressure swing adsorption (PSA), which removes carbon dioxide and other impurities. Oftentimes, an ammonia plant will exist downstream from the hydrogen plant, whereby the hydrogen is reacted with nitrogen to yield ammonia.

Isolation challenges posed by severe-service environments

The combination of high temperatures and pressures results in a severe-service environment which presents significant challenges to fluid isolation requirements. At the reformer and steam generator, temperatures and pressures can reach or exceed 1500°F and 1500 psig respectively. These elevated temperatures and pressures are prevalent throughout various modules of and applications within the SMR process, including the reformer, boiler feed water, feed gas lines, steam drum bridles, purging applications and blowdown applications.

Beyond the SMR island and at the ammonia section of the plant, these temperature and pressure challenges also persist throughout the nitrogen applications – as an example, nitrogen supply valves to compressors and flare headers may reach or exceed 4000 psig at 400°F.

As the world advances on renewable energy initiatives, hydrogen has been gathering strong momentum as a ‘strategic pillar’ for energy transition, as it is a clean-burning molecule and a potential substitute for fossil fuels. Combined with carbon capture and sequestration (CCS) technologies, the SMR process enables the conversion of conventional hydrogen production, referred to as ‘grey hydrogen’, to the production of low-carbon hydrogen, otherwise known as ‘blue hydrogen’. For blue hydrogen to become economically viable as a primary energy source, the costs across the entire hydrogen value chain, including production, storage, distribution, etc., need to be reduced to meet the DOE’s cost targets for future automobiles and other applications. With respect to hydrogen production, the SMR process remains as the most cost-effective method as compared to others, such as electrolysis. Although the SMR process is considered a mature technology, both commercial and environmental optimisation opportunities exist and are being realised via sustained higher temperatures and pressures in particular areas of the process. For example, the Hydrogen Council and McKinsey & Co. assert that: “conducting ATR [autothermal reforming] at higher temperatures can also increase the methane-to-hydrogen conversion rates, resulting in lower methane content in the product gas, further reducing emissions.”1 As a result, new plants are designed to run much hotter and at higher pressures in specific applications and modules as compared to those in existing facilities. Moreover, the efficacy of a true closed-loop system without leaks to atmosphere become critically important, from both a commercial and environmental perspective. As such, reliable isolation with positive shutoff becomes not only much more challenging for the valves in these applications, but also vitally important for the entire production process.

Valve selection from general service to severe-service

At lower temperatures and pressures, torque-seated gate valves, often equipped with either solid Stellite® or Stellite-welded overlay trims, may suffice for applications that do not require tight shutoff. Torque-seated valve designs involve the application of substantial forces to the valve components to adequately seal against line pressure. Over time, these forces wear down the critical sealing components of these types of valves resulting in shortened product lives vs those of position-seated valve designs.

As temperatures and pressures rise, gate valves are often replaced by Y-pattern globe valves, similarly equipped with either solid Stellite or Stellite-welded overlay trims, to achieve improved shutoff performance at initial installation. Unfortunately, the improved shutoff performance of globe valve is offset by substantial pressure drop across the valve and short product longevity.

The design of a globe valve involves a tortuous flow path that results not only in a high pressure drop (reduced Cv), but also in persistent erosion to its sealing elements. Furthermore, globe valves, like gate valves, are also torque-seated, which must be ‘hammered-down’ to seal against line pressure, resulting in sustained wear to the internal components of the valve. Combined with multi-turn and rising stem mechanics, the sealing efficacy of globe valves is often compromised by these factors, resulting in packing leaks to atmosphere throughout the life of the valve. In addition to packing leaks, seat leaks often plague the performance of globe valves, as a temperature differential between the upstream and downstream sections of a closed globe valve results in thermal expansion of the inlet side of the valve vs thermal contraction of the outlet portion of the valve, which contains the plug. As such, the sealing efficacy of the plug and seat is compromised, and the globe valve will leak through downstream...

Reference

- McKinsey & Co., ‘Hydrogen Insights: A perspective on hydrogen investment, market development and cost competitiveness’, (February 2021).

Written by Robert Hsia, UnionTech, USA.

This article was originally published in the August 2021 issue of Hydrocarbon Engineering magazine. To read the full article, sign in here or register for a free trial subscription.

Read the article online at: https://www.hydrocarbonengineering.com/special-reports/16082021/severe-service-solutions/

You might also like

The Hydrocarbon Engineering Podcast - Process safety improvements in the downstream sector

In this episode of the Hydrocarbon Engineering Podcast, Lara Swett, Vice President of Technical & Safety Programs, American Fuel & Petrochemical Manufacturers (AFPM), joins us to explain how the downstream sector has continued to improve its process safety record.

Tune in to the Hydrocarbon Engineering Podcast on your favourite podcast app today.