Rethinking industrial combustion: part 2

Challenges associated with post combustion technologies

SCR and FGR technologies can be effective, but they also create a number of significant issues for operators of combustion equipment in the oil and gas industry. First and foremost, these solutions require expensive and complex designs, which can have significant implications on the performance and cost of combustion systems. For example, because SCR systems perform best within narrow temperature bands, they require the installation of control units to ensure that the exhaust gas temperatures are within range for the reaction to occur. SCR systems also require additional space and infrastructure (mechanical, electrical, structural), which may not be available at the site or the plant. Similarly, FGR technologies require additional ductwork, blowers and fans. This technique can be significantly energy intensive, resulting in increased energy consumption and reduced efficiency.

The use of hazardous chemicals such as ammonia can actually pose new environmental threats. An over injection can cause an ammonia slip and the release of hazardous compounds into the atmosphere, which can be harmful in the event of direct exposure.

The underlying issue with SCR and FGR technologies is that they operate in the post combustion process, meaning they are attempting to mitigate the problem of emissions after they have been created, rather than solving the issue at the source. Recently, a new generation of technologies has entered the market with a new take on air pollution control. Instead of functioning as filters or scrubbers, these technologies operate at the flame level, eliminating varying levels of pollutants directly at the source.

LNB and ULNB burners

Low NOX (LNB) and ultra low NOX (ULNB) burners for boilers and process heaters typically use some variant of staged combustion and delayed mixing. During this process, fuel rich and fuel lean zones are deliberately formed in diffusion flames to bring down average temperatures and inhibit NOX formation. Unfortunately, these solutions can also have a major impact on operating costs. LNBs and ULNBs create elongated flames, which are inherently less stable and can cause poor flame patterns in the heater and lead to potentially severe impingement of flames on process tubes. Furthermore, LNBs and ULNBs have more limited operating ranges, compromising turndown in order to maintain stability. Aside from these trade offs, these burners alone have not shown they are capable of meeting the levels of NOX emission required by upcoming regulations, and may require the use of external flue gas recirculation or SCR to achieve these objectives.

Problems associated with elongated flames

Elongated flames create a range of issues in industrial burners and process heaters in the refining and petrochemical industries. While fuel and air momentum are strong near the burner, the momentum falls sharply away from the fuel nozzles, often resulting in lazy and buoyant flames, prone to entrainment by furnace currents (often leading to flame impingement on process tubes). This undesirable phenomenon causes a host of problems, the most severe being tube overheating, which in turn leads to coking inside the process tubes. As a thermal insulator, coke interferes with the normal heat transfer and causes overheating on the outside tube wall, an issue commonly referred to as hot spots, which can severely weaken the tubes and accelerate tube failure. Furthermore, intermittent flame impingement can gradually corrode the oxide layer inside the tubes, thinning the tube walls and leading to catastrophic tube ruptures.

Advanced technologies

Advanced systems, which can be easily applied to traditional burners, boilers and process heaters, provide a radically different approach to combustion, enabling significant NOX emissions reductions at the flame level. This can be achieved without the limitations experienced by LNBs and ULNBs, while increasing burner efficiency and actually improving operations and management costs. Not only are these technologies more cost effective to operate compared to traditional emissions control solutions, but also require less upfront investment and they can be easily retrofitted into existing systems.

The daily fluctuations in oil prices directly affect operations and future planning for oil and gas companies, which tend to be risk averse and careful when it comes to adopting new technologies. Particularly when oil prices are low, oil companies tend to reduce investments in new technologies and instead focus on incremental improvements. As a relatively low cost investment, advanced emissions control technologies offer an additional economic incentive to operators, independently from gas price variations.

By lowering NOX emissions to record breaking lows (at or below 5 ppm) these systems provide oil and gas operators with an economical compliance pathway to meet environmental regulation. A recently developed technology in particular enables such results, by making use of a porous ceramic matrix through which the combustion is uniformly sustained, while simultaneously reducing flame length by up to 80% (Figure 2) and better controlling flame patterns and heat distribution, eliminating the risk of flame impingement.

Figure 2. ClearSign's Duplex™ technology: reduced flame length.

This ducted ceramic surface increases thermal efficiency, optimising heat transfer in the system’s radiant section and avoiding excessive loading of downstream convection heat transfer surfaces. Additionally, this technology achieves better fuel air mixing, which allows for reduced excess air and resulting in incremental fuel efficiency (Figure 3).

Figure 3. ClearSign’s Duplex™ technology: improved fuel-air mix.

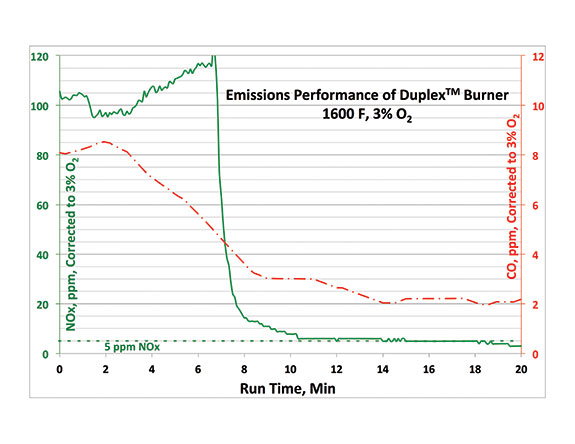

Without the flame impingement, a frequent problem with LNBs and ULNBs, process tubes will require less frequent decoking and both process and steam tubes will enjoy lower failure rates and longer lifetimes, thus enabling operators to avoid downtime and the expense of unscheduled maintenance. Figure 4 shows how a simple combustion system, when modified to operate with an advanced porous ceramic matrix, can significantly abate NOX emissions, lowering concentrations from more than 100 ppm to 5 ppm or below.

Figure 4. Duplex NOX emissions performance.

Conclusion

As increasingly stricter environmental regulations are imposed in major markets around the world, oil and gas operators are searching for a solution that can reduce emissions without sacrificing system performance. Today, operators have the opportunity to choose from a variety of technologies that can help them abate NOX emissions. As previously discussed, the traditional methods provide limited benefits at high capital and operational costs. Advanced systems reduce pollutants at the source, eliminating the need for post combustion treatment technology and significantly lowering both capital and operating costs while yielding a positive return on investment for system operators.

Written by Roberto Ruiz, ClearSign, Combustion Corporation, USA.

Edited by Claira Lloyd

Read the article online at: https://www.hydrocarbonengineering.com/special-reports/19062015/industrial-combustion-p2/

You might also like

The Hydrocarbon Engineering Podcast - Education and training for every phase of the insulating system design process

In this episode of the Hydrocarbon Engineering Podcast, Brandon Stambaugh, Owens Corning Director for Technical Services, joins us to discuss engineers’ demand for education and training to support the critical phases that affect the performance and longevity of insulating systems.

Tune in to the Hydrocarbon Engineering Podcast on your favourite podcast app today.