Continuous Emission Measurement

Published by Bella Weetch,

Editorial Assistant

Hydrocarbon Engineering,

Hot/Wet measurement means analysing the stack gas sample on an as-is basis, and maintaining the integrity of the sample from extraction through analysis. The prime objectives of Hot/Wet measurement are to prevent the condensation of acid mist or water vapour and to maintain water soluble compound compositions. The sample is generally analysed at a temperature different from the process temperature - this may be hotter or cooler - but the sample composition is never altered. There is no need to adjust analyser reported concentrations to account for the water that was removed when a cooler or chiller is used.

Let us focus on a specific measurement that is commonly found in refineries, natural gas processing plants and steel mills. The measurement of sulfur dioxide (SO2), hydrogen sulphide (H2S), nitrogen dioxide (NO2) and other gases are often reportable gas emissions from sulfur recovery units (SRU) located in these types of production facilities. Hot/Wet analysis is well suited to the measurement of these gases for the following reasons:

- In dry gas systems, when water is removed, components can sometimes be selectively removed. For example, if a sample containing a finite amount of SO2 is cooled to below the water dewpoint, the SO2 dissolves in the water phase reducing the SO2 being measured in the vapor phase. The net result is incorrect measurements.

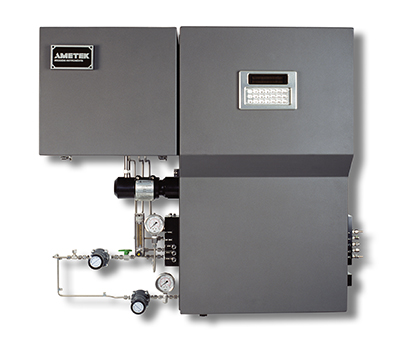

- Measuring the sample on an as-is basis is compatible with mass emission measurement (kg/h of SO2). If the stack gas velocity is measured on a water-included base, the component of interest should also be measured in that way. AMETEK 909 and 910 analysers have the option of mass measurement.

- A Claus SRU incinerator can generate significant quantities of sulfur trioxide (SO3) at high temperatures during upset conditions (sulfur entrainment, off-ratio, etc.). SO3 is very corrosive and can damage sample handling systems if the sample is over cooled to the point where SO3 condenses.

- In a Hot/Wet system, the sample is extracted and drawn through the analyser with an air-driven eductor. There is no mechanical pump to maintain.

AMETEK SO2 analysers can handle a wide range of process and sample conditions. AMETEK analysers have been successfully installed at thousands of sample locations, to perform measurements in SRUs and other processing units.

To find out more about AMETEK Process Instruments, simply click here.

Read the article online at: https://www.hydrocarbonengineering.com/special-reports/06072021/continuous-emission-measurement/

You might also like

The Hydrocarbon Engineering Podcast - Education and training for every phase of the insulating system design process

In this episode of the Hydrocarbon Engineering Podcast, Brandon Stambaugh, Owens Corning Director for Technical Services, joins us to discuss engineers’ demand for education and training to support the critical phases that affect the performance and longevity of insulating systems.

Tune in to the Hydrocarbon Engineering Podcast on your favourite podcast app today.