Maximising process efficiency with Compander technology

Published by Kristian Ilasko,

Digital Content Coordinator

Hydrocarbon Engineering,

The chemical and petrochemical industries are major sources of industrial CO2 emissions, which makes reaching carbon neutral a major challenge for the sector. Nevertheless, almost all of the world's leading chemical and petrochemical companies have committed to achieving net zero by 2050 and have developed their own decarbonisation roadmaps to achieve this goal.

Among the many different approaches formulated in these roadmaps, some key technologies and strategies have become apparent, which include the use of green or blue hydrogen, CCUS (carbon capture, utilisation and storage), the electrification of operations, the use of renewable energy, and improving energy efficiency. Recovering and converting all sources of waste energy into useful outputs significantly improves energy efficiency of many operations. The advantage of this approach is that companies can reduce their energy consumption without the need to change core processes. Relatively easy to do, engineers need to simply tap into existing energy streams and reuse them.

A major focus in this regard is the recovery of waste heat, which is typically the largest form of energy lost on chemical and petrochemical plants. Key to recovering and reusing waste heat is compressor and expander technology, key components of not only industrial heat pumps and mechanical vapor recompression (MVR), but also in the creation of liquid hydrogen, and in CCUS projects.

Recovering waste heat

The method of recovering waste heat depends on its temperature level. In many gas processes, waste energy is contained in a pressurised gas stream. In this case, an expander can recover the waste heat and also the pressure energy, a process that has been used in the industry for a long time.

Recovery can broadly come under two concepts:

- Converting the mechanical energy of the expander to pressure energy: the expander is connected to a compressor stage;

- or the expander is connected to a generator and the mechanical energy is converted to electricity.

Alternatively, a combination of the two: the expander is connected to a motor-generator compressor train, and either the expander reduces the load on the motor, or it runs the entire train, generating electricity and driving the compressor at the same time.

The basic gas expansion turbine: the expander

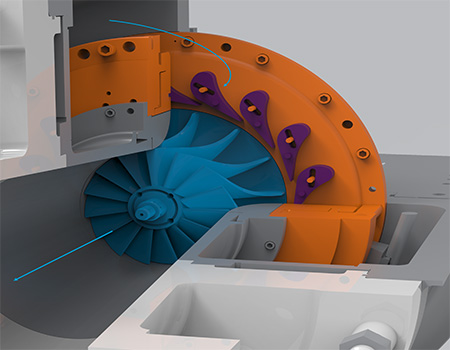

Radial inflow turboexpander technology refers to the flow direction through the impeller/wheel, with capacity control via adjustable inlet guide vanes (IGVs). IGVs ensure efficiency remains stable at a high level over the turndown range. After entering the turbine housing, the gas flow is accelerated through the IGVs with Mach numbers of up to 1.4 before the impeller inlet. During acceleration through the IGVs, the static pressure decreases, resulting in a static enthalpy drop of around 50%.

The accelerated gas then flows through the impeller, where energy and momentum are transferred from the gas to the impeller and thus to the turbine shaft. The advantage of the radial inflow over an axial design is its compact and robust structure at high-stage efficiency. The maximum possible enthalpy drop per expansion stage can be up to 220 kJ/kg. The minimum pressure ratio should be equivalent to an enthalpy drop not smaller than 30 kJ/kg. It is important to note that there doesn’t have to be a high-pressure ratio: in many cases, most of the energy comes from the temperature and not from the pressure and increasing the temperature has quite a high effect on the recoverable energy.

Atlas Copco Gas and Process has more than four decades of experience designing and installing Companders. They are designed to handle all gases and deliver volume flows of up to 450 000 m3/h across eight stages, at a rated power of up to 30 MW. Derived from the words ‘compressor’ and ‘expander’, Companders integrate both technologies in the same unit. This integration relies on integrally geared centrifugal compressor technology, which has the flexibility to integrate a turboexpander...

This is an abridged version of Atlas Copco’s white paper, titled ‘Efficient Compander Technology’. Download the full version of this white paper for free here.

Read the article online at: https://www.hydrocarbonengineering.com/special-reports/01082025/maximising-process-efficiency-with-compander-technology/

You might also like

The Hydrocarbon Engineering Podcast

A podcast series for professionals in the downstream industry featuring short, insightful interviews. Subscribe on your favourite podcast app to start listening today.