Pavilion8 from Rockwell Automation

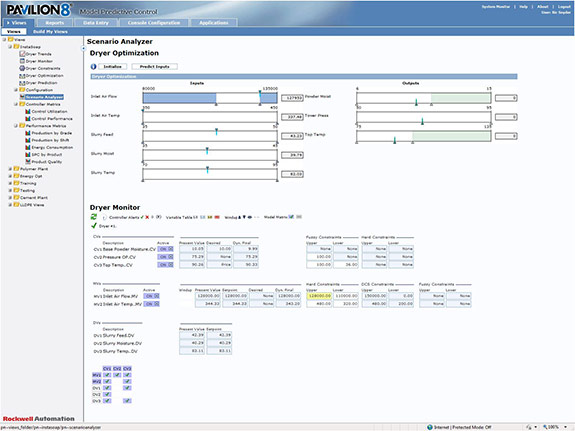

At ACHEMA, Rockwell Automation showcased Pavilion8 Model Predictive Control (MPC) software which now delivers a more user friendly configuration environment, step by step prompts, warning diagnostics and flexible work flows to simplify building, maintaining and adjusting highly complex process models.

Michael Tay, Pavilion Project Manager said, “Pavilion8 software has long been known as being among the most powerful software for solving highly challenging control problems, and is now also among the easiest to use. The solution builder tools within the software now offer MPC configuration in a modern Windows environment, giving users a more familiar and streamlined experience. For example, user can now execute right click mouse operations and complete copy and past type actions to develop applications in the software, helping them deploy their solutions faster and reduce training and adoption times.”

Pavilion8 MPC v5.0 software remains control system independent, but smoothly integrates with the PlantPAx process automation system from Rockwell Automation and includes four key enhancements.

Windows based configuration and support

An improved overall user experience for expert and inexperienced users alike begins with the updated, Windows based solution builder tools, which improve work flow by enabling users to create a customised working environment and providing access to online help.

Multivariable run time controller

Users will also discover new time saving features in version 5.0. The robust run time controller has been updated to allow users to add new predictive disturbance measures in half the time as the previous version, and easily compare differences in MPC application versions. Users now can easily sort, rename, add, delete, compare and copy MPC variables and software supporting a flexible work flow, which can help reduce troubleshooting time. Output variables, such as power moisture from an industrial dryer or reactor pressure in a vessel, can also be used as inputs to a non-linear control model to help simplify deployment. Multiple developments that enhance integrating control models simplify and improve run time performance.

Continuous controller monitoring

Users can now configure their process models with specific metrics for production, quality, energy usage and other factors. They can also continuously measure their processes according to these metrics and use historical records to track ongoing benefits. The software incorporates new data efficiencies to provide a faster and more responsive trend environment, particularly for those supporting larger and more demanding systems.

Supports modern browsers and operating systems

To make the Pavilion8 experience more consistent with other software environments and improve overall ease of use, Rockwell Automation redesigned the software’s user interface to align with current technology standards. This includes support for newer browsers like Internet Explorer 11 and operating systems, such as Windows 2012.

Edited from press release by Claira Lloyd

Read the article online at: https://www.hydrocarbonengineering.com/product-news/07072015/achema-rockwell/

You might also like

The Hydrocarbon Engineering Podcast - Travelling towards sustainability: exploring the economics of e-fuels

In this special episode, a panel of experts from Johnson Matthey, A.P. Moller - Maersk, Honeywell, HIF Global and the Methanol Institute provide a clear analysis of the factors influencing e-fuel pricing, the economic challenges, and strategies for cost reduction.

Tune in to the Hydrocarbon Engineering Podcast on your favourite podcast app today.