Developing infrastructure for CCUS

Published by Ellie Brosnan,

Editorial Assistant

Hydrocarbon Engineering,

Hydrogen, as an energy carrier, is one of the main keys to a net zero future. Unfortunately, that key cannot open all doors for now, especially as many industries are seeking alternatives to existing energy sources with a lower carbon footprint. One potential accelerator for net zero energy is carbon capture, utilisation, and storage (CCUS), with various industries able to use this technology for significantly reducing carbon dioxide emissions.

The CCUS industry is quite diverse and is now entering its commercialisation and scaleup era with various solutions and applications, each with a unique implementation nuance. From a high-level point of view, carbon capture techniques can be divided into post-combustion capture, pre-combustion capture, direct air capture, and biological capture.1 All these techniques, except biological capture, require quantity and quality measurement of carbon dioxide for regulatory compliance, process efficiency optimisation, and improved safety.

According to the International Energy Agency (IEA), the overall use of CCUS in a wide list of industries is projected to grow rapidly – with CCUS projects operational, under construction, and planned – increasing from an estimated 80 million t in 2024 to just over 400 million t in 2030. The natural gas processing and LNG industry is currently the leader in this sector, with 70% of the 2024 projects.2

For decades, carbon dioxide has been widely used in industries such as oil and gas (especially for enhanced oil recovery), food and beverage (for carbonation and preservation), manufacturing (for welding and chemical production), agriculture (for greenhouse enrichment), and fire suppression. However, in most of these applications, carbon dioxide emissions were treated as a byproduct rather than a significant environmental issue. But, as compared to these existing industrial uses, the CCUS industry brings completely new challenges and a higher level of complexity.

The notion of capturing and storing carbon dioxide as a climate change mitigation strategy gained prominence more recently as the focus shifted toward reducing the greenhouse gas emissions that contribute to global warming.

Going down the carbon dioxide value chain, one clearly sees a need for transportation, utilisation, and storage of carbon dioxide. As with many other industries, the amount of carbon dioxide transferred from one party to another must be traced, often with custody transfer applications. This article will explore applications along this value chain, and it will show how carbon dioxide can be measured at critical points to improve operations.

CCUS overview

An example of a CCUS value chain is depicted in Figure 1.

The process of carbon dioxide capture varies significantly depending on the particular industrial process and the maturity of the technology in use. For example, transportation depends heavily on the required distance of transport and available infrastructure.3 Pipelines are the most cost-effective transportation method from an operating standpoint (Figure 2), and they are commonly connected to multiple points of carbon dioxide feed and ownership handover, thus creating the need for harmonisation.

The utilisation and storage links of the CCUS value chain will each vary depending on location and capabilities. For example, collected carbon dioxide can be used to create carbon-neutral or carbon-negative fuels, chemicals, and building materials.4 Carbon dioxide can be stored in different ways: mineral storage and deep geological storage, which includes enhanced oil recovery, saline aquifers, and more.5

The global need to reduce carbon dioxide emissions requires measurement and analysis of carbon dioxide. With flow meters being the key instrument for measurement, they are critical for successful reporting and accountability.

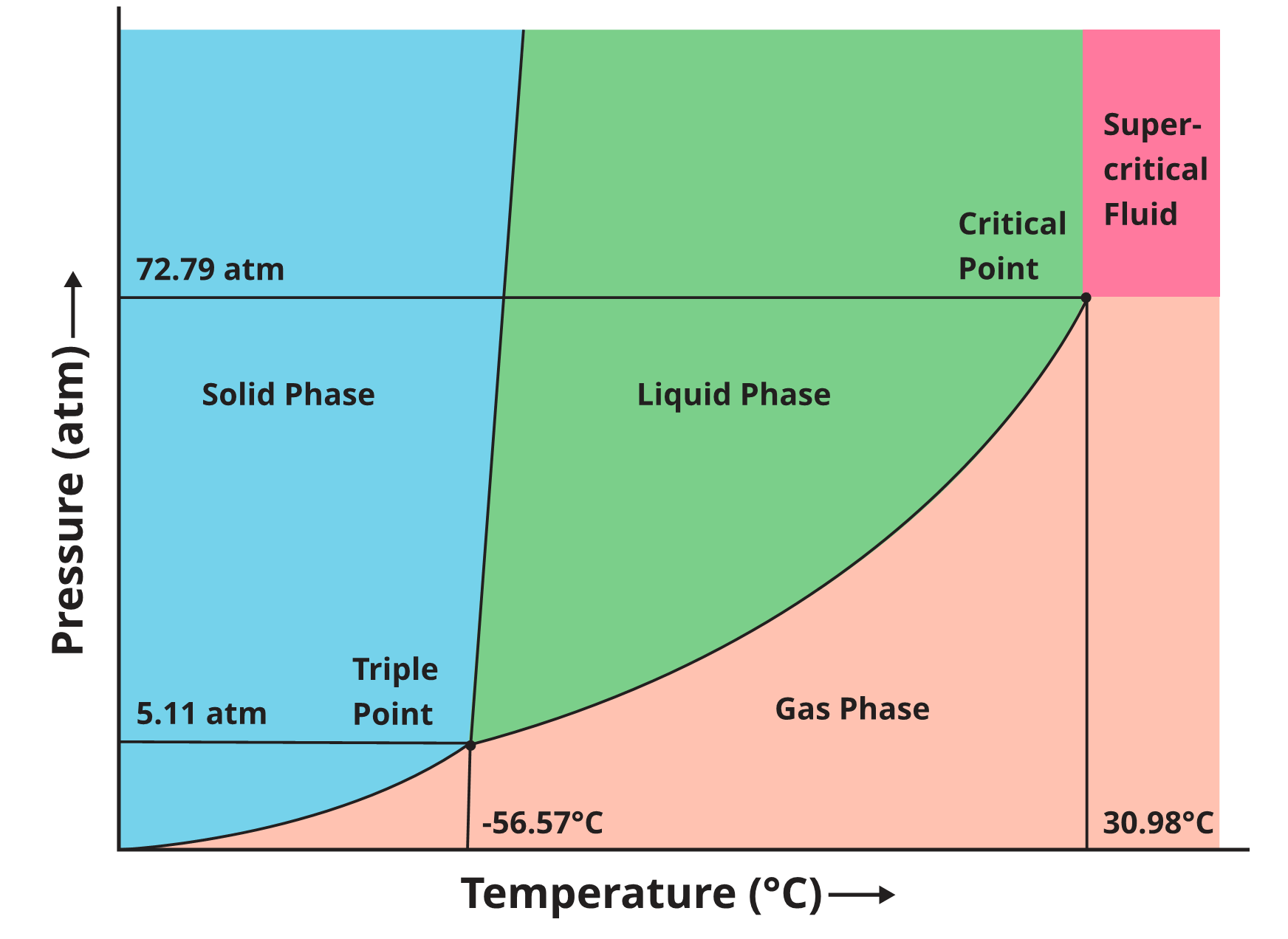

This can be challenging because of a unique physical property of carbon dioxide, namely that all three states – gas, liquid, and supercritical – can occur at typical industrial operating temperature ranging from -40 to +50 °C, and at an operating pressure ranging from 100 - 200 bar (Figure 3). This is very different from hydrogen and methane, for example, each of which only transforms to liquid from gas phase at significantly lower temperatures, ranging from -160 to -255 °C.

This characteristic of carbon dioxide creates both opportunities and challenges for CCUS. Carbon dioxide can be liquified relatively easily – beneficial for transportation and some other use cases – but phase changes at relatively low temperatures and pressures make flow measurement quite complicated as the density of carbon dioxide is sensitive to process operating conditions.

Measurement complexity

The diverse CCUS techniques and the requirement of scaleup create measurement complexities. While there are likely to be situations where a given company has all the elements of a CCUS chain under the same corporate roof, it is more likely that multiple companies are involved in the chain. Some of the hand-offs may be actual changes of ownership, but others may be transport for hire.

This occurs frequently with large scale pipelines and distribution systems, similarly to how hydrocarbon commodities are traded around the world. Systems for the exchange of natural gas and other products are well established and have operated for years, but such was not always the case. The practices of custody transfer have evolved over the years, driven by distribution complexity and technological improvements. The common denominator to all custody transfer operations is using the appropriate measurement technology, qualified by external testing groups in keeping with accepted standards. Such approvals prove to both sides of a transaction that the numbers are accurate, thereby reducing the chance for a dispute.

For transactions between two parties, the accurate measurement of the amount of carbon dioxide molecules (quantity) is crucial for day-to-day activities. The best approach to accomplishing this is making reliable and trusted measurements by choosing the right technology, and by using well-tested and certified instruments.

Over the past few years, a theoretical assessment of the different flow meter technologies has been performed by various authors, and extensive overviews have been published.6 To prove these theoretical concepts, tests have been recently performed for meters measuring carbon dioxide flow. So far, two sites have performed calibration tests on a large scale with various flow meters: DNV Energy Systems (Netherlands) Fuel and Flow Advisory group, Groningen, the Netherlands, and FortisBC Measurement, Penticton, British Columbia, Canada.

DNV test conditions simulated pipeline transportation, typical of medium/low-pressure shipping via marine vessels and vapour return during vessel loading. These types of extensive tests offer all industry participants confidence in the reliability of the measurements for tested technologies and meters from different manufacturers. Sonic nozzles, turbine flow meters (TM), Coriolis flow meters (CMF), ultrasonic meters (USM), vortex meters, and some other technologies have been tested against an accurate and unique reference system.

Reliable measurement of carbon dioxide mass flow

With CCUS applications, the frame of reference is often tons of produced carbon dioxide because this parameter directly represents the number of molecules removed from the atmosphere. Also, much of the required reporting for CCUS is in mass as opposed to volumetric, that is by weight as opposed to volume. Consequently, the mass flow of carbon dioxide is becoming an industry standard across the CCUS value chain.

A leading technology for mass flow measurement is flow meters based on the Coriolis principle. These types of meters provide a direct and native mass flow measurement, with a variety of diagnostic capabilities to check meter health and to more accurately assess changes in a process.

The research mentioned above, along with theoretical assessments, has shown that Coriolis flow meters can reliably make mass flow measurements of carbon dioxide across a wide range of conditions. This finding positions this technology as the leading solution for CCUS measurement applications. The DNV test results cover almost all possible gaseous carbon dioxide applications. The test outcome supports the conclusion that Coriolis flow meters perform according to a very tight specification of ±0.25% for gas measurement. Similar results were demonstrated for measurements made under liquid and supercritical carbon dioxide conditions.7

The results from DNV tests collaborate with the conclusions of the FortisBC tests. The combined results of these two tests facilitated the certification of Emerson’s Coriolis mass flow meters for custody transfer of carbon dioxide under varying operating conditions.

As the DNV findings summarised: “Emerson Elite Coriolis flow meters are OIML R 137 certified for measurement of gases including carbon dioxide with accuracy class 1.0. The performance of the Coriolis flow meters in this joint industry project (JIP) further illustrates the capabilities of the Emerson Coriolis flow meter to generate accurate mass measurement even under challenging operating conditions. Furthermore, the results demonstrate insensitivity to the various impurities of the carbon dioxide measurement.”

Emerson’s Micro Motion ELITE Coriolis flow meters are certified by DNV and OIML R 137 (Figure 4). They can thus be deployed to support the critical carbon dioxide capture, transport, and sequestration processes, helping to build a reliable infrastructure.

Consultation with Emerson experts can help companies active in the CCUS value chain pick the right product from the range of available meters for their applications, with assurances that these meters will perform as designed, while complying with all applicable industry standards.

References

1. https://www.sciencedirect.com/science/article/pii/S0016236123003897

2. https://www.iea.org/data-and-statistics/data-tools/ccus-projects-explorer

3. https://www.sciencedirect.com/science/article/pii/S1364032123010079

4. https://www.iea.org/reports/putting-co2-to-use

5. https://www.bgs.ac.uk/discovering-geology/climate-change/carbon-capture-and-storage/

6. https://www.sciencedirect.com/science/article/pii/S2950160124000111

7. https://www.tuvsud.com/en-gb/-/media/regions/uk/pdf-files/event-documents/gfmw-2024/technical-papers/3-ccus-1-yaser-alghanmi_emerson.pdf

Notes

All figures courtesy of Emerson except as noted.

Written by Aleksandr Druzhkov.

Read the article online at: https://www.hydrocarbonengineering.com/special-reports/06062025/developing-infrastructure-for-ccus/

You might also like

The Hydrocarbon Engineering Podcast

A podcast series for professionals in the downstream industry featuring short, insightful interviews. Subscribe on your favourite podcast app to start listening today.