Shaista Mallik, Seeq, explores how modern software tools, such as AI, ML, and advanced analytics, are empowering processors to drive efficiency and profitability throughout their enterprises.

The hydrocarbon industry is undergoing a major transformation. Facing pressure to reduce environmental impact, adopt circular operations, and embrace digitalisation, oil and gas companies are rethinking their production methodologies. But achieving lasting efficiency gains requires a strong digital foundation upon which to build.

Leading organisations are investing in digital transformation, powered by artificial intelligence (AI), machine learning (ML), and advanced analytics. These types of technologies are no longer optional in the industry, but are instead strategic imperatives to drive enterprise-wide modernisation.

When combined with the domain expertise of subject matter experts (SMEs), AI, ML, and advanced analytics generate new insights from complex process data, enabling smarter and faster decision-making with minimal capital investment. By embedding these capabilities into existing daily workflows, companies can optimise performance, empower their workforces with actionable insights, and solve long-standing operational challenges in more efficient ways, increasing both sustainability and profitability.

This article describes digital transformation at a high level, then explores two case studies that exemplify how organisations are using innovative technologies to achieve it.

A digital transformation gameplan

Deloitte finds that, “digital transformation is all about becoming a digital enterprise – an organisation that uses technology to continuously evolve all aspects of its business models (what it offers, how it interacts with customers, and how it operates).”1 In analytics, this means automating manual tasks, like data aggregation and cleansing, so teams can focus on uncovering insights, diagnosing issues, and driving improvement.

A common misconception is that organisations need a fully developed IT/OT architecture before pursuing digital initiatives. In reality, modern self-service analytics applications provide immediate value, regardless of the company’s digital maturity.

Even companies with legacy systems can start small using modern self-service analytics tools. These tools access data directly where it resides, reducing time to value and empowering teams to generate actionable insights faster. By simplifying access to information and accelerating decision-making, advanced analytics help organisations realise tangible business outcomes and move further along their digital transformation journey.

These journeys often start with three key phases: evaluation, implementation, and scale and optimisation.

Phase 1: evaluation

Effective evaluation begins with engaging the right cross-functional stakeholders – both technical and administrative – to ensure business needs are fully addressed and the workforce is aligned. By breaking down siloes, teams can identify high-value applications that deliver quick wins and build organisational confidence.

The next step is selecting software that enables rapid implementation, seamless data access, and easy integration within existing enterprise architectures to help teams achieve results in days, rather than months.

Phase 2: implementation

For successful implementation, leaders should prioritise those quick wins that deliver measurable business value and identify changemakers who can champion progress across the organisation.

Oftentimes as teams move from evaluation to execution, they try to advance too quickly and tackle the hardest problems first. Instead, focusing on ‘low-hanging fruit’ accelerates return on investment (ROI), builds organisational confidence, and demonstrates that digital transformation makes employees’ work easier in the long run. A series of early successes can help reduce resistance and foster buy-in from the broader workforce.

During this stage, changemakers naturally emerge. These are the individuals among all levels of the organisation with the unique ability to influence others and drive enthusiasm within their teams. Leaders should empower and amplify these advocates to strengthen support for new technologies and procedures.

Because changemakers have pre-established trust and credibility within their departments, they play pivotal roles in building confidence and demonstrating value. When effectively leveraged, their energy can accelerate company-wide adoption and propel an organisation toward full-scale optimisation.

Phase 3: scale and optimisation

As teams enter the scale and optimisation phase, it is critical to remember that while individual digital transformation projects have defined goals, transformation itself is an ongoing journey. Each improvement strengthens the foundation for future innovation and positions teams for ongoing value creation. Therefore, a continuous improvement and sustainment plan should be a core project deliverable to help keep teams focused on value creation while adapting to evolving business needs.

Equally important is ensuring that employees who are adopting new technologies have the tools, support, and confidence to succeed. This includes training, use case guidance, internal knowledge sharing, and clear feedback loops with project leaders and changemakers. By embedding continuous learning and collaboration, organisations not only maintain momentum, but also maximise the long-term impact of their digital transformation efforts.

Processors are establishing these practices and optimising their operations by leveraging AI, ML, and advanced analytics. With user-friendly and collaborative tools that unlock time-series and industrial data insights, these technologies are empowering teams to drive efficiency, make better data-driven decisions, and boost profitability.

Implementing intelligent liquid pipelines and terminal operations

One leading North American pipeline operator – transporting approximately 5.8 million bpd of crude oil and liquids through an extensive network of pipelines and terminal facilities – was facing significant challenges that limited operational efficiency and drove up production costs. Its data was fragmented across sites, with inconsistent tag naming conventions that made cohesive analysis difficult and hindered insights into pipeline and terminal performance.

Operators also struggled with limited real-time visibility, as accessing and comparing historical performance metrics required extensive manual effort. Maintenance practices were largely reactive, resulting in costly unplanned downtime when equipment failures demanded immediate attention. Additionally, although vast sensor data was collected, limited analytics capabilities restricted opportunities for operational optimisation and complicated regulatory compliance.

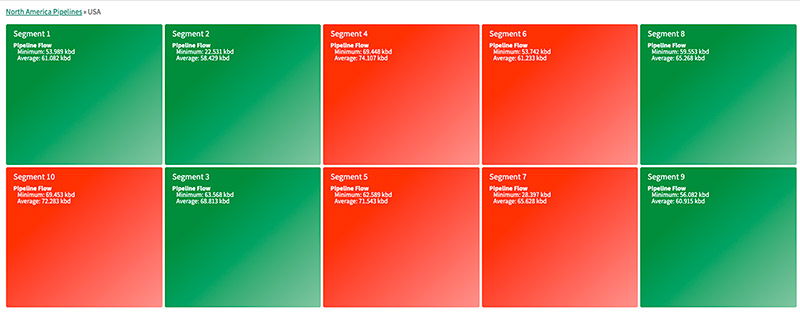

Figure 1. A leading North American pipeline operator references a dashboard in Seeq to highlight anomalies across assets, identified by pipeline name and units.

To address these issues, the company launched a comprehensive digital transformation initiative, beginning with standardised tag naming conventions and an asset framework (AF) hierarchy. These foundational changes enabled the integration of Seeq, an advanced analytics, AI, and monitoring platform, to monitor time-series data from multiple systems and detect patterns and anomalies to support predictive maintenance. Custom graphics linked to AF templates provided intuitive visualisation, which empowered data-driven decision-making (Figure 1).

The initiative produced:

- Data standardisation, which improved analytics reliability.

- Real-time monitoring that accelerated anomaly detection.

- Predictive maintenance protocols, reducing downtime and operational costs.

- Proactive resource allocation, which enhanced operational efficiency.

By combining advanced analytics with structured data, the company transformed its pipeline operations, achieving greater efficiency, reliability, and safety.

Tackling meter freezes to optimise gas delivery

For a major global oil and natural gas provider, frozen meters were threatening profitability, which was causing measurement errors and costly product giveaway across its 32 000 mile pipeline network with a processing capacity of 7.4 billion ft3/d. Traditional rule-based approaches for detecting freeze events proved unreliable and resource-intensive because they required constant manual updates, could not adapt to varying conditions, generated numerous false positives, and often missed detections.

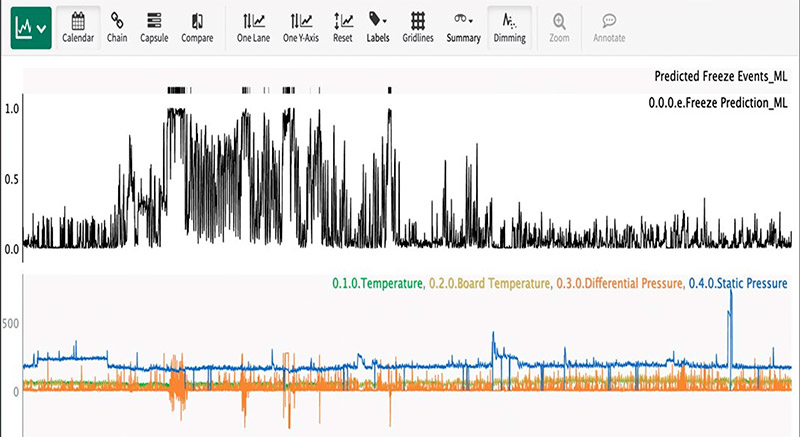

Figure 2. A major oil and natural gas provider used Seeq Workbench to review data, predict freeze events, and model results.

To address these challenges, the company partnered with Seeq to simplify access to its extensive meter data and improve data quality. Using the software platform, SMEs labelled past freeze events, while data scientists collaborated with engineers to build ML models (Figure 2). These efforts enabled moving beyond rigid rules toward more accurate, predictive insights.

The team established a fully automated workflow within Seeq, encompassing data pre-processing, model configuration, and automated retraining to maintain accuracy as operating conditions changed. Predictions fed directly into visual dashboards and reports, providing stakeholders with real-time visibility into potential freeze events.

This approach enabled proactive interventions, reducing product giveaway and saving millions of dollars annually, even with modest accuracy improvements. Beyond financial gains, the solution enhanced scalability for managing large datasets, fostered data-driven collaboration, and empowered engineers to focus on higher-value work. By linking prediction to actionable insights, the provider realised the full operational and economic benefits of ML deployment.

Innovate to remain competitive

As the hydrocarbon market landscape remains demanding, industry players are increasingly adopting AI, ML, and advanced analytics capabilities into their workflows. These technologies are empowering organisations to overcome long-standing challenges and enhance efficiency.

By focusing on strategic digital initiatives and fostering cultures of continuous improvement, companies are unlocking new levels of performance within their operations, driving productivity, quality, and profitability.

Reference

- ‘Digital transformation: a PRIMER’, Wired, https://www.wired.com/brandlab/2019/10/deloitte-digital-transformation-a-primer/